In the realm of woodworking and metalworking, achieving a flawless finish is akin to the Holy Grail—sought after by many but attained by few. The secret, however, lies not in some esoteric knowledge passed down through generations, but in the mastery of the tools and materials at our disposal. Among these, the 5-inch 8-hole hook and loop sanding disc stands out as a beacon of efficiency and effectiveness. Today, we embark on an in-depth exploration of these sanding discs, understanding their benefits, and learning how to utilize them to achieve that coveted flawless finish.

Introduction to Hook and Loop Sanding Discs

Hook and loop sanding discs have revolutionized the way we approach sanding tasks. These discs are designed with a backing that easily attaches to and detaches from a sanding tool, thanks to their Velcro-like surface. This convenience in swapping out discs allows for a more streamlined workflow, significantly reducing downtime between sanding grits. Moreover, the ease of use is complemented by the even distribution of sanding pressure, which ensures a uniform finish across the workpiece.

The innovation does not stop at their functionality. The versatility of these discs, compatible with a wide range of tools and suitable for various materials, from wood to metal, positions them as a staple in any workshop. Whether you’re a professional craftsman or a weekend DIY enthusiast, understanding how to leverage these discs can significantly elevate the quality of your work.

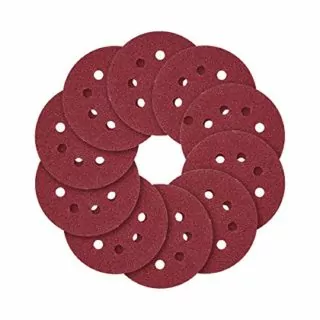

Understanding the 5-Inch 8-Hole Hook and Loop Sanding Discs

The 5-inch 8-hole hook and loop sanding disc is a specific variant designed to offer optimal dust extraction during the sanding process. The eight precisely arranged holes align with the dust collection system of the sanding tool, allowing for a cleaner working environment. This feature is particularly beneficial in maintaining the integrity of the sanding disc and extending its lifespan, as it prevents the buildup of dust particles that can clog the abrasive surface.

This dimension and design are not arbitrary but are instead the result of careful consideration of ergonomics and efficiency. The 5-inch diameter offers a balance between coverage area and maneuverability, making it ideal for a wide range of projects, from large surface areas to more intricate pieces. The incorporation of hook and loop technology facilitates swift transitions between different grit sizes, ensuring that you can progress through the sanding stages with minimal interruption.

Benefits of Using Hook and Loop Sanding Discs

The advantages of using hook and loop sanding discs are manifold. Firstly, the time efficiency gained from the quick-change system cannot be overstated. This feature alone makes them a preferred choice for projects with tight deadlines or for those seeking to optimize their workflow. Additionally, the uniform application of pressure results in a more consistent finish, reducing the need for rework and adjustments.

The durability of these discs is another significant benefit. Designed to withstand the rigors of heavy use, these discs maintain their effectiveness over time, translating to cost savings and fewer replacements. Furthermore, the improved dust extraction not only contributes to a healthier work environment by reducing airborne particles but also enhances visibility during the sanding process, allowing for more precise work.

Different Types and Grits of Hook and Loop Sanding Discs

Navigating the array of hook and loop sanding discs available can be daunting. These discs come in a variety of grits, ranging from coarse (40-60 grit) for removing substantial material, to ultra-fine (800-1000 grit) for polishing and finishing touches. The choice of grit depends on the stage of your project and the desired finish. Starting with a coarse grit and gradually working your way up to a finer grit is a proven strategy for achieving a smooth, blemish-free surface.

In addition to grit variations, sanding discs are also made from different materials to suit various applications. Aluminum oxide discs are a popular choice for general-purpose sanding, offering a good balance between durability and cost. For more demanding applications, such as sanding hardwoods or metal, zirconia alumina discs may be preferable due to their superior longevity and cutting ability. Silicon carbide discs are ideal for finishing metals and hardwoods, as they provide an exceptionally smooth finish.

Choosing the Right Hook and Loop Sanding Disc for Your Project

Selecting the appropriate sanding disc is crucial to achieving the desired outcome. Consider the material you are working with and the stage of your project. For rough shaping or removing old finishes, start with a lower grit disc. As you progress towards the final finish, incrementally increase the grit size to refine the surface.

The type of material the disc is made from should also be taken into account. For versatile applications, aluminum oxide discs are a safe bet. However, for specific tasks or materials, choosing a disc made from zirconia alumina or silicon carbide may yield better results. Understanding the characteristics of these materials and how they interact with your workpiece will guide you in making an informed decision.

How to Use Hook and Loop Sanding Discs Effectively

To maximize the potential of hook and loop sanding discs, proper technique and usage are paramount. Begin by ensuring the disc is securely attached to the sanding tool and that the dust collection system (if available) is aligned with the holes in the disc. Apply even pressure during sanding, moving the tool in a consistent pattern to avoid gouging or uneven wear on the disc.

It’s also important to let the tool do the work—pressing too hard can lead to premature wear of the disc and potential damage to the work surface. Regularly check the disc for signs of wear and replace it when necessary to maintain optimal performance. By adhering to these practices, you can extend the life of your sanding discs and achieve better results.

Tips for Achieving a Flawless Finish with Hook and Loop Sanding Discs

Achieving a flawless finish is the culmination of patience, technique, and the right tools. Here are some tips to guide you:

Start Coarse, Finish Fine: Begin with a coarse grit to quickly remove material and gradually move to finer grits to smooth out the surface.

Keep it Clean: Regularly clean the surface you’re sanding and the sanding disc itself to prevent the buildup of dust and debris, which can mar your finish.

Even Pressure: Apply consistent pressure and keep the sander moving to avoid creating divots or uneven surfaces.

Test and Adjust: Always test your technique and grit progression on a scrap piece of material before moving to your final piece.

Protect Your Work: Once you’ve achieved the desired finish, protect your work with an appropriate sealant or finish, depending on the material and intended use.

Maintaining and Caring for Your Hook and Loop Sanding Discs

Proper maintenance of your sanding discs extends their lifespan and ensures they’re ready for your next project. After each use, remove the disc from the sander and gently clean it with a soft brush or cloth to remove any residual dust. Store your discs in a dry, flat position to prevent them from warping or becoming damaged. Additionally, inspect your discs regularly for signs of wear or damage and replace them as needed to maintain the quality of your work.

Conclusion

The journey to a flawless finish is one of precision, patience, and the right tools. With 70PCS of 5-inch 8-hole hook and loop sanding discs at your disposal, you are well-equipped to tackle any project, big or small. By understanding the nuances of these discs, choosing the right type and grit for your project, and applying best practices in their use, you can achieve exceptional results that speak to your skill and dedication. Remember, the art of sanding is not just in the removal of material but in the preparation of a surface that stands the test of time and reflects the beauty of craftsmanship.